Address: Room 201-5-5,2nd Floor,East Office Building,45 Beijing Road,Qianwan Bonded Port Area,Qingdao Area,China (Shandong) Pilot Free Trade Zone (A)

Phone: (+86) 17663923752

E-Mail: edward@sinditech.cn

Cane Feeder Table

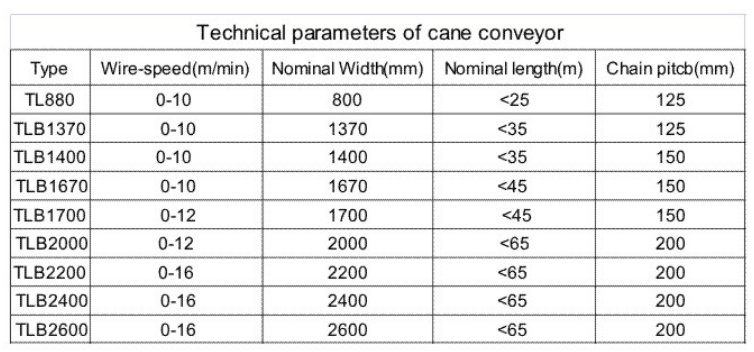

Cane Conveyor

Cane conveyors are used for even and continuous conveyance of sugarcane, during which the cane is simultaneously shredded and crushed by shredders for convenience of juice extraction. Cane conveyors adopt scraping belt structure which ensures large conveying capacity and steady operation. Power transmission adopts speed-regulating motors to ensure even feeding of material.

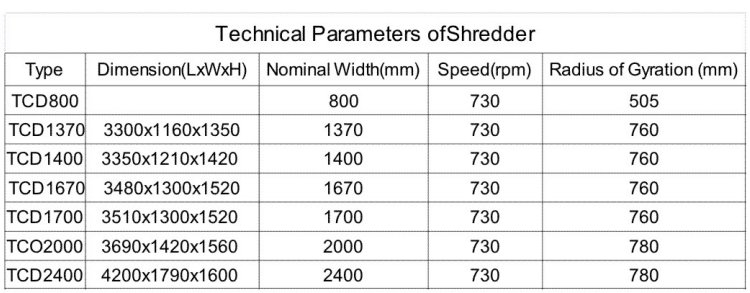

Cane S hreder

Main usage: The sugarcane is shredded from strips to filiform material, reducing the sugarcane size while increasing the weight, and the smooth surface of the sugarcane rind is destroyed, thus increasing the friction factor and the pulling force between cane layers, so as to increase the production capacity of mills and raise the extraction rate of sugar content. Shredders produced by our company are divided into two major series as Blade Type(TCD series) and Pendulum Type (Tonga machine). The TCD series shredders adopt dual spiral blade arrangement which provides such performances as high crushing rate of sugarcane, more filiform of sugarcane material, evenly arranged sugarcane layers, stable operation and small power consumption.

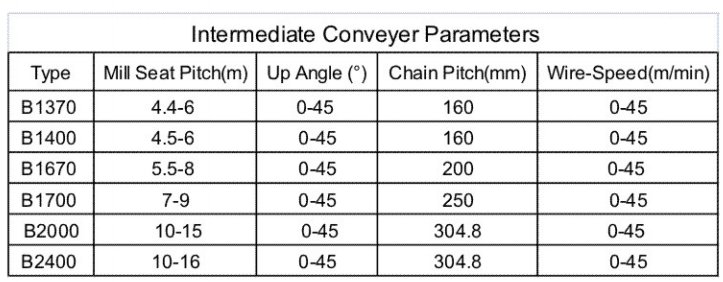

Rake Conveyor

Main usage: used for conveying sugarcane material between two mills. Its advantages are below:

1. Rake teeth feeding is adopted, thus the conveying capacity is high.

2. Large inclination angle.thus elevation of cane material is high, bringing about convenience to install overhead vessel to

3. Tank bottom sealed, no juice and bagasse leakage

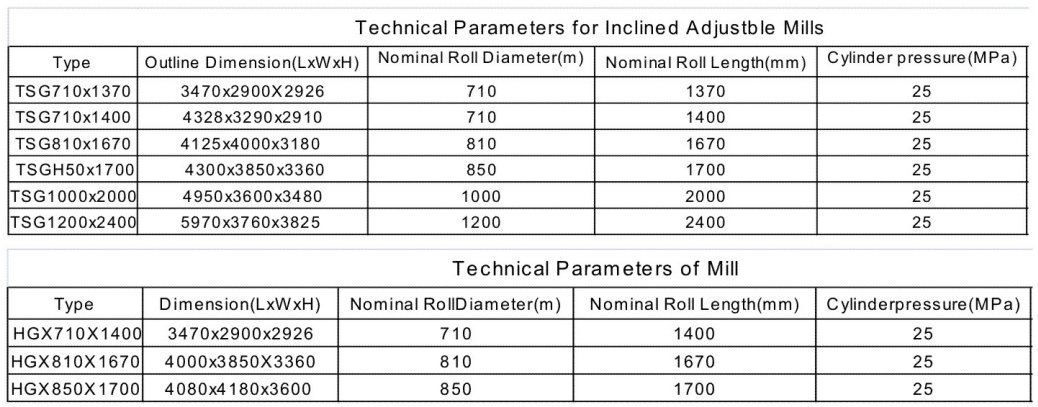

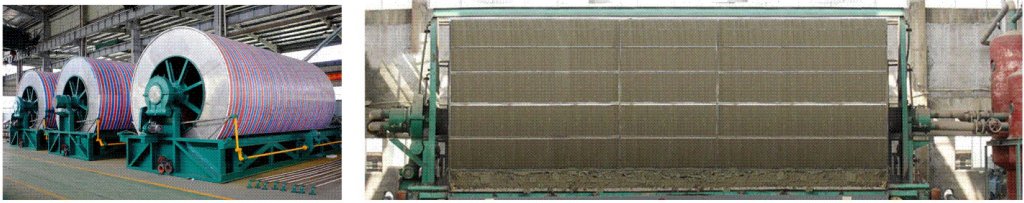

Sugarcane Mill

Mills of TSG (Inclined adjustable) series and HGX (constant ratio type) series are our leading products. Mills are main equipments to extract cane juice in cane sugar plants. After having been fed into the mills, the cane is crushed again and gets its cell tissues broken under certain pressure, thus forcing its juice to drain. and then is to be crushed and repeatedly permeated by multiple mills for elevation of the extraction rate Power transmission of mills may select such mode as traditional motor matching with gear reducer, and gear box driving square shaft for driving rotation of the milling rolls, or select such mode as motor matching with planetary gear reducer, flexible coupling driving rotation of the milling rolls, or hydraulic motors or planetary gear reducer to be hung on the heads of the milling rolls for direct driving, flexible coupling.

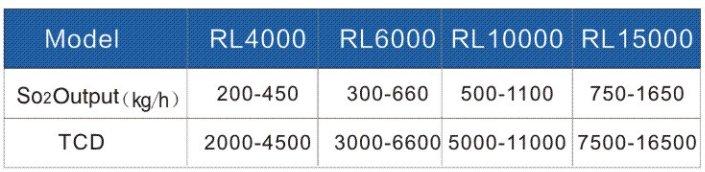

Sulfur Burner System

Sulpitation neutralization section is the throst of sugar production quality control. The Auto- control Spray Sulfur Burner System has realized the automatic control of sulphitation process which has the following features

1.Stable Sulphitation. The sulphitation intensity can be arbitrarily set at between 10-32ml, and the fluctuation is

2.Liquid level of mixed juice tank is stable. No overflow, no exhaust

3.Only occupied 30% of the area compare with the old equipment the system has no leakage

4.The quality of sugar increased significantly.

Molasses Extractor

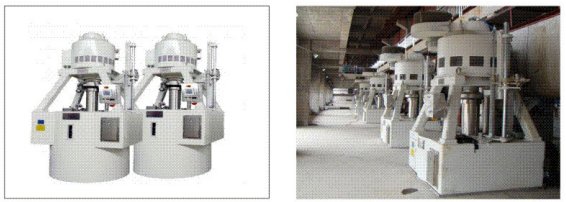

Centrifuge

Suction Machine/Filter

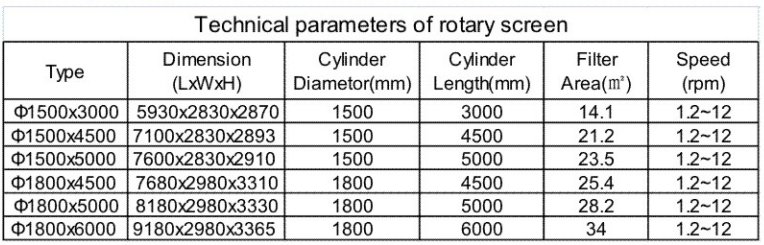

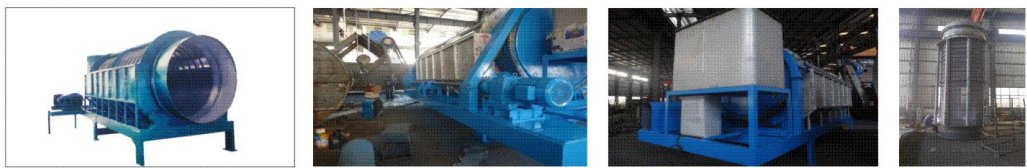

Rotary Sieve & Vibrating Screen

Rotary Sieve Series

Mainly used for filtration of bagasse in mixed juice and provided with large processing capacity. Less juice in the bagasse and high filtration efficiency compared with traditional curved sieves.